The electronics and robotics industry carves a path to future technology with each innovation. Therefore, consumer electronics is rapidly taking control over the design to support the functions of the products designed. It brings high demand for different shapes and forms of electronic products for daily use. Get in-depth detail for the rapid sheet metal solid quote in the information below.

The electronics industry is getting a breakthrough with the integration of rapid prototyping to cover and gain the confidence of the ultimate consumer.

What is it? The rapid prototyping in the electronics and robotics industry is to make the prototyping phase more convenient using the digital mantra during customization. It helps industry-leading manufacturers maintain quality and standards alongside the full functionality of consumer products. Rapid prototyping method includes CNC machining, 3D printing, CNC milling, and vacuum casting for the prototypes that can treat for commercial production.

With accuracy and precision in rapid prototyping, the solutions can be treated for flexible design, reliability, and customization.

In robotics:

Rapid prototyping for the robotics industry has also gained attention with incarnated demand in the international customer section. It assists the industry by supporting different designs and functionality to test the robotics mechanism and concepts. This successful robotics prototyping will then be trabeated to each industrial unit to lower the cost of production compared to labored units.

The process of rapid prototyping in robotics is also used to convey the usefulness of the non-technical actions of the public. What limits the robotics industry in the rapid prototyping phase? Firstly, the robotics industry faces limited strength in using plastic parts that can not be tested accurately for force exception and consumption.

Nonetheless, rapid prototyping is assisting the robots industry to fiercely get through the prototyping stage and get to the commercial production of robotics for the general public and industrial units. Moreover, this process has been tested to support the demonstration, validation, modification, redesigning, and constructive testing of the robotics design to meet the demand in the market.

Benefits of rapid prototyping to the robotics industry:

- The quick turnaround time that speeds up commercial production,

- Cost-effectiveness,

- No restriction for part complexity. As prototyping supports geometric and precision in design, it assists the robotics industry through cheap solutions.

- All parts are customizable. Therefore flexibility in designing is also available.

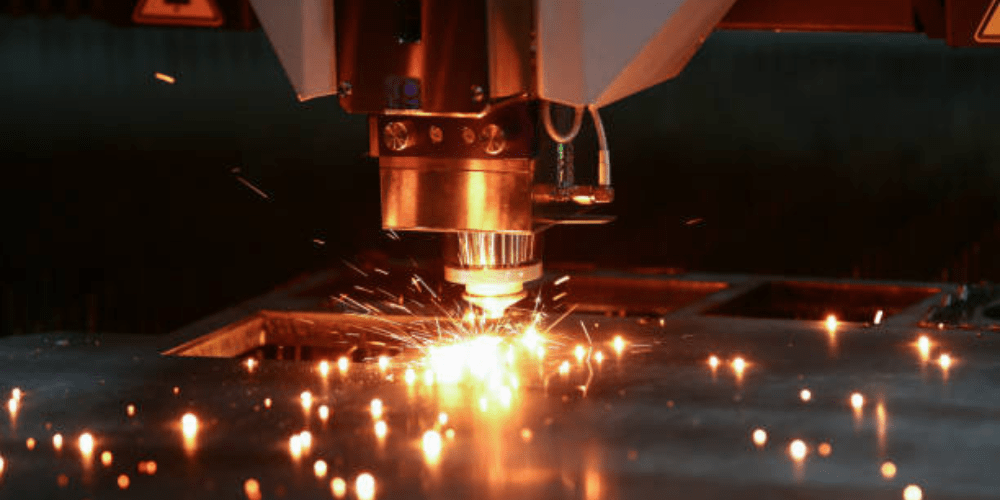

Rapid sheet metal prototyping:

With rapid sheet metal prototyping, the physical mockup of the final products is easily displayed to the investment sector and the public. It increases their interest in creating assets that take the economy and market to the future of electronics and robotics alongside innovation.

The purpose of supporting rapid sheet metal prototyping in electronics and robotics is to test the prior concept for mass production capacity. Nonetheless, it also lowers the cost of production, giving the designers leverage to make necessary changes.

Furthermore, it lets the industry check for possible drawbacks without getting into the mass production stage without testing the prototypes.

The access and reach of electronics and robotics with the leverage of rapid prototyping is taking the industries to the next scale. Not only can they test the innovative designs that are already in demand in the market. But they can also check the impossible solutions that are only possible for the future of electronics and robotics technology.